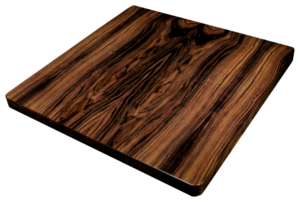

Restaurant furniture deals with constant wear and tear due to constant customer traffic. We’ve all gone into a restaurant and instead of a nice tabletop immediately noticed instead of the scratches and various marks and nicks all over it. That’s one of the reasons why many restaurateurs choose to cover tables with linens. In addition, to try to make their tables last longer by covering them with linens, restaurant owners also utilize linens to provide a more sanitary table to patrons. But there’s actually an option to provide such a durable, high-quality finish that no linens are necessary: AcralyteX.

AcralyteX is an acrylic resin that is chemically engineered to be more scratch, mar, chemical, and heat resistant than traditional furniture finishes, such as epoxy resin, polyester resin, urethane, and conversion varnishes. Unlike other tables, AcralyteX tables aren’t susceptible to common usage issues like wearing quickly, yellowing from the sunlight, and getting heat rings from hot dishes and cups.

Tired of seeing rapid deterioration of tables coated with traditional resin finishes, we spent years researching and developing AcralyteX. The end result was a proprietary chemical formulation that uses a UV curing process to reach our elevated level of protection for wooden tabletops. So that means that when an AcralyteX table is properly cared for, it will outlast a similar table that doesn’t have the AcralyteX finish. Another table may be cheaper up front, but a non-AcralyteX coated table only lasts one to two years on average, compared to the five to seven years a table with AcralyteX will last. That’s why AcralyteX is such a better value. And, depending on the finished look desired, it’s available in a variety of options, including full filled, gloss, satin, open grain, and open grain satin.

Tired of seeing rapid deterioration of tables coated with traditional resin finishes, we spent years researching and developing AcralyteX. The end result was a proprietary chemical formulation that uses a UV curing process to reach our elevated level of protection for wooden tabletops. So that means that when an AcralyteX table is properly cared for, it will outlast a similar table that doesn’t have the AcralyteX finish. Another table may be cheaper up front, but a non-AcralyteX coated table only lasts one to two years on average, compared to the five to seven years a table with AcralyteX will last. That’s why AcralyteX is such a better value. And, depending on the finished look desired, it’s available in a variety of options, including full filled, gloss, satin, open grain, and open grain satin.

Another big benefit to AcralyteX is that in addition to its beautiful and durable finish, it has antimicrobial properties. It can be cleaned with practically anything, so there’s no need to cover it with linens in order to keep the table sanitary.

Another big benefit to AcralyteX is that in addition to its beautiful and durable finish, it has antimicrobial properties. It can be cleaned with practically anything, so there’s no need to cover it with linens in order to keep the table sanitary.

It’s time to go linenless with a table that can stand up to normal wear and tear, as well as provide customers with the best—and cleanest—restaurant experience possible. So give us a call today. Your table just isn’t complete without AcralyteX.