At Table Topics, we’ve spent decades crafting only the highest quality custom commercial dining tables, and we’re excited to announce that we will once again be bringing these products to the upcoming Hospitality Design Exposition & Conference (HD Expo) in fabulous Las Vegas.

To be held May 2-4 at Mandalay Bay in Las Vegas, the HD Expo is the industry’s leading hospitality conference and trade show, and it’s an event known for showcasing new products and services for the hospitality industry.

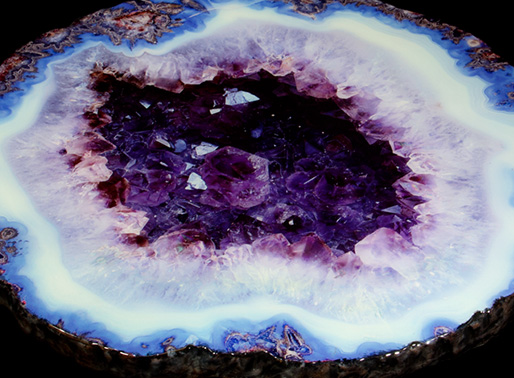

In Las Vegas, we will also have a hands-on test for attendees to see up close just how special our exclusive Acralyte finish is for commercial tables. Acralyte is an acrylic resin that is chemically engineered to provide greater scratch, mar, chemical, and heat resistance than traditional furniture finishes (like epoxy, resin, polyester resin, urethane, and conversion varnishes). To illustrate that, we will have a scratch test set up in our Las Vegas booth for anyone to test the industry-standard urethane top against our Acralyte finish.

Attendees to our booth in Las Vegas, will also get a chance to speak directly with three of our team members who have all been with our company for more than 10 years. Hayden Powell (president), Melissa Land (director of sales and marketing), and Tammy Allen (customer service) will be available and ready to chat with anyone wanting more information about our unique design capabilities.

So don’t miss out on this exciting opportunity to visit with us and see the latest tabletops at our booth in fabulous Las Vegas, #2822, at Mandalay Bay! We look forward to seeing you there!

Email Melissa Land at melissa@tabletopics.biz if you’d like to connect at this year’s expo.

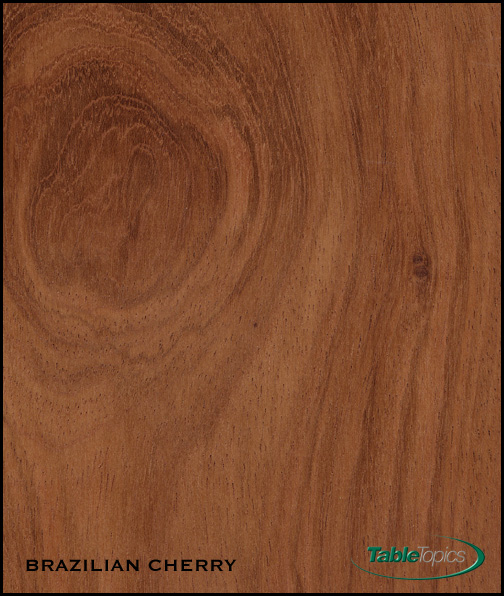

Investing now in differences like

Investing now in differences like

features filigree design with a solid bowed maple frame.

features filigree design with a solid bowed maple frame. re logos and specialized designs.

re logos and specialized designs.