Start with the finish you know will outlast the rest.

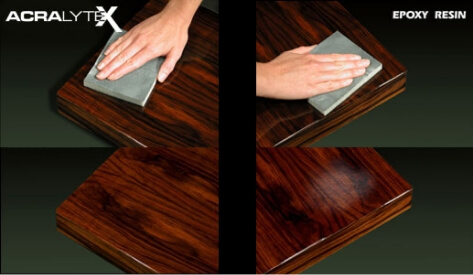

Scratched. Worn. Yellowed. We know those are not words you hope to use to describe your commercial dining tables after just a few months of use in your establishment. But the reality is that traditional finishes wear quickly, yellowing from sunlight, sporting unsightly heat rings from hot plates and cups, and accumulating a gummy finish as cleaning chemicals and alcohol take their toll.

Acralyte serves as a superior replacement for traditional finishes such as epoxy resin, polyester resin, lacquer, conversion varnish and polyurethane. The acrylic resin is cured using ultraviolet light, undergoing a series of unique processes that result in a finish unmatched in quality and durability. Finish your custom wood table tops with Acralyte, a finish engineered to endure the elements.

Acralyte is an acrylic resin that is chemically engineered to achieve greater scratch, mar, chemical & heat resistance than traditional furniture finishes (such as epoxy resin, polyester resin, urethane and conversion varnishes). Acralyte’s proprietary chemical formulation allows for it to achieve these elevated levels of protection on a consistent basis by using a UV curing process.

By curing the finish with UV lights (instead of air, heat or chemical hardeners) the finish is fully cured after it passes through a UV light oven. Traditional finishes can be cured enough to ship but may take weeks or months before they are fully cured. This can result in an initial “break in” period during which the finish is susceptible to a greater risk of damage than after a full cure is achieved. Even when fully cured, though, traditional furniture finishes still fail in comparison to Acralyte. Scratching, marring, chemicals and heat can cause all furniture finishes to fail before the life of the furniture has run out and this is especially true with restaurant table tops. Commercial table tops are used multiple times on a daily basis. If the finish can’t withstand that environment it is only a matter of time before the tables will have to be replaced. Acralyte offers an unmatched level of scratch & mar resistance in the furniture industry. Nevertheless, dinnerware with abrasive undersides and other coarse items used in service can still cause the finish to scratch or become hazy.

An excellent choice that adds dimension and protection to tables that require additional coverage (such as multi-layered or textured surfaces) or to tables designed to have more depth (such as veneers or digital images).

The full filled coating offers the most protection to a table. This is because there are additional layers of finish that help protect against impact damage as well as scratching, marring, chemicals and heat. Because there additional layers of finish there is a little more cost associated with the full filled option. Also, if something does manage to scratch the surface that scratch will be a little more apparent because it is suspended above the substrate of the table. While Acralyte II surpasses other finishes in withstanding hot temperatures, we caution you to avoid placing hot (over 190°F) dishes directly on the surface. Acralyte II is not available for solid wood tables because the additional layers of coating create stability issues with the solid wood.

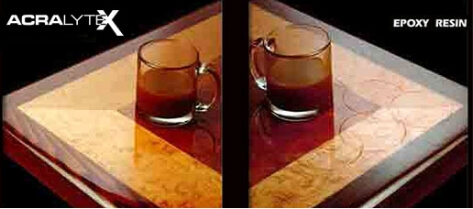

Full Filled Gloss is the clearest finish offered and is typically used in very contemporary designs. This finish offers the most clarity in the detail of the design of the table and can really make a statement in the right environment.

A word of caution regarding gloss: because gloss is clear and shiny it tends to show any residue that’s left on the table. So more time and attention is required to properly clean and maintain the table to avoid everything from fingerprints to spills that aren’t adequately cleaned up from showing on the finish. (Think fingerprints on glass.) The gloss finish is only available in the Full Filled finish option. It’s not offered as an open grain option because attaining this level of smoothness & clarity requires the extra build that the full filled finish provides. Achieving this look is also the most labor intensive process and a more expensive option than satin or matte finishes.

Full Filled Satin is a silky, smooth finish that actually has a pearl like shine.

Full Filled Matte delivers a smooth, subtle look and shows little to no sheen. Both of these Acralyte finishes offer the extra protection of the full filled finish and are recommended in high use restaurant settings. As with all Acralyte finishes, the Full Filled Satin and Matte options offer unparalleled protection against scratching, marring, heat and chemicals. Each can be completely customized to a specific gloss reading, as well.

An exceptional option that provides a hard, durable furniture finish with the smooth appearance of an elegant, hand-rubbed oil finish.

Open Grain Acralyte is applied as a thin coating which shows off the texture of the wood grain but still provides the same scratch, mar and chemical resistance that it’s Full Filled counterpart provides. It even offers higher heat resistant properties, allowing dishes to be served at up to 250°F instead of 190°F. Keep in mind, though, that while the Open Grain Acralyte finish provides a more natural look and feel to your restaurant table tops, this version of Acralyte can’t prevent the substrate that it’s protecting from moving if hit hard enough. The result of heavy impact can leave dents or dings in the dining table. Clients that typically choose this finish prefer the more natural look that Open Grain Acralyte provides and don’t find the small dents or dings that could be caused in service objectionable or a cause for concern. Also, since there are fewer layers of finish in this version, Open Grain Acralyte does offer some cost savings over Full Filled Acralyte because there are less operations and materials required to produce this style of dining table.

Open Grain Satin is a silky finish that actually has a pearl like shine.

Open Grain Matte delivers a subtle look and shows little to no sheen. Both of these Acralyte finishes help to enhance the natural look and feel of the wood grain that’s being protected and are recommended in high use restaurant settings. As with all Acralyte finishes, the Open Grain Satin and Matte options offer unparalleled protection against scratching, marring, heat and chemicals. Each can be completely customized to a specific gloss reading, as well.

When properly used and cared for, restaurant tables with Acralyte will consistently outlast a similar style table that doesn’t have an Acralyte finish. The value of extending the product’s life is what makes Table Topics the most cost effective restaurant table manufacturer in the industry.

When a less expensive table that may last 1-2 years is compared to Table Topics expected 5–7 years of product life (with many documented cases of 10 or more years of life) the cheaper table is actually much more expensive in the long run.

Table Topics’ biggest demand from both individual and corporate accounts centers around a clientele that is budget driven for long term success.

Everything from the materials that are used in the product to unique production operations not typically incorporated in furniture manufacturing are tightly monitored and controlled to ensure that the product can make it through a rigorous production process.

For example, Table Topics uses specially formulated glues that are designed to withstand extended drying cycles of solid wood panels and the heat and energy that the product goes through during the UV curing process.

Without these glues, the woods used in the tables run the risk of being damaged when going through the production process or failing in service. And this is just one example of the many unique processes that makes the Acralyte process truly unique.

We often get asked if we could re-finish tables that were not produced by Table Topics so that they could have the Acralyte finish. As much as we try to provide the best service to all of our customers or potential customers, we never end up re-finishing another supplier’s tables.

Table Topics has this policy because we can be almost certain that specific fail-points were not guarded against during the production from another manufacturer. Since those tables didn’t go through the Acralyte production process they won’t hold up through the Acralyte finishing process or once they are put into service.